Your cart is currently empty!

Repairing and overhauling all Caterpillar engines requires manufacturers guidance

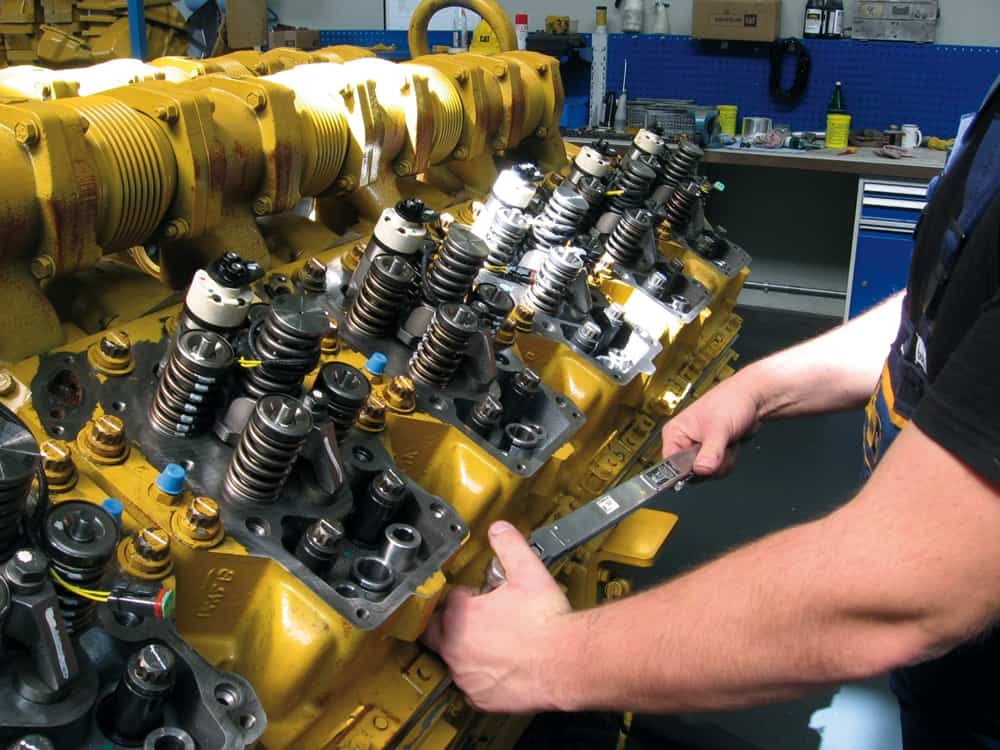

Caterpillar engines are some of the most reliable and powerful engines in the world. They power many of the world’s largest and most important machines, from construction equipment to ships and trains. But even the most reliable engines need maintenance and repair, and when it comes to Caterpillar engines, that means manufacturers need to be involved in the process. This article will discuss the importance of manufacturer guidance when repairing and overhauling Caterpillar engines, and the steps and benefits of doing so.

What is Caterpillar Engine Repair?

Caterpillar engine repair involves restoring the engine to its original condition and performance. This includes replacing worn or damaged parts, cleaning and inspecting the engine, and making any necessary repairs or modifications. In some cases, the entire engine may need to be rebuilt or overhauled. This is a complex process that requires specialized knowledge and highly trained technicians.

Why is Manufacturer Guidance Needed?

Caterpillar engines are complex machines, and repairing and overhauling them requires a great deal of knowledge and experience. Without the guidance of the engine’s manufacturer, repairs can be difficult or even impossible. Manufacturer guidance ensures that the repairs and overhauls are done correctly and safely.

What Are the Steps Involved?

The steps involved in repairing and overhauling a Caterpillar engine vary depending on the type of engine and the extent of the repairs needed. Generally, the process involves disassembling the engine, inspecting and cleaning the individual components, replacing any worn or damaged parts, and reassembling the engine. It is important to follow the manufacturer’s instructions carefully to ensure the engine is properly repaired and ready for service.

What Are the Benefits of Repairing and Overhauling?

Repairing and overhauling a Caterpillar engine can have several benefits. It can extend the life of the engine and reduce the likelihood of costly repairs in the future. It can also improve the engine’s performance, reduce emissions, and increase fuel efficiency.

What Are the Challenges?

Repairing and overhauling a Caterpillar engine can be a complex and time-consuming process. It requires specialized tools and equipment, and technicians must be highly trained and experienced. It can also be expensive, as parts and labor can add up quickly.

How Can Manufacturers Help?

Manufacturers can help by providing detailed instructions and guidance for repairing and overhauling their engines. They can also provide technical support and advice, and offer training and certification programs for technicians. This can help ensure that repairs are done correctly and safely, and can help reduce the cost and complexity of the process.

Repairing and overhauling a Caterpillar engine is a complex and time-consuming process. It requires specialized knowledge and highly trained technicians, as well as the guidance of the engine’s manufacturer. Following the manufacturer’s instructions and taking advantage of their technical support and training programs can help ensure the engine is properly repaired and ready for service. With the right guidance, Caterpillar engines can be reliable and powerful for years to come.